As a leading supplier of waterproof and breathable laminates, eVent has achieved a technological milestone. By 2025, the company will offer a product line that is completely free of PTFE- and PFAS-based products, setting a new industry standard. Plus, they’re introducing an innovative lightweight product that’s sure to turn heads. “Defy the elements” is eVent’s new slogan, and it perfectly encapsulates the technological strides the company has made.

By 2025, eVent will phase out PTFE-based membranes and PFAS technologies in the West. Additionally, eVent started developing and introducing bio-based membranes even before the pandemic. “Defy the elements” also heralds an entirely new era for eVent, blending decades of technological expertise in high-performance materials with a commitment to responsible action. President Chad Kelly discusses the changes and introduces eVent’s new products and technologies.

You are about to launch a new product: stormburstLT. What kind of product is it?

stormburstLT is an extension of our existing product platforms that have been developed from end-user applications. For example, we have the alpineST product platform, which is focused on extreme applications, and we have stormST, previously available under the name eVent BIO, which is more performance outdoor and lifestyle-focused.

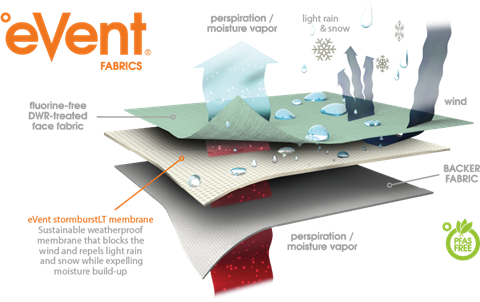

The category that has been a gap for us is the ultralight technology platform, which is focused on aerobic use. That’s where stormburstLT comes in. So, from a technical point of view, we’ve introduced a super-light membrane, about five microns thick combined with lightweight woven and knitted fabrics to create a product with very high moisture vapor transport and high breathability at a lower level of waterproofness.

Why the focus on breathability?

Waterproofing is not always the most important selling point. Breathability and water vapor removal from the inside of the jacket are top priorities. But of course, stormburstLT does offer some weather protection. Normally with eVent we have always focused on complete weather protection first, but in this case, we are focusing more on breathability, stretch comfort, and fit for the aerobic user.

What applications do you see for stormburstLT?

We intend to offer something for the fast and light crowd, for example cycling, running, or skimo. At the same time, stormburstLT has some very interesting applications for urban users. You don’t need the same technology in the city that you need to climb Mount Everest. So, with stormburstLT we can offer an outerwear solution for urban and activewear markets where the properties of the fabric, such as weight and breathability, are much more important. Additionally, the fabric is light enough not to affect the loft of insulation layers, for example. This is where stormburstLT is perfect.

When is stormburstLT coming onto the market?

We launched it at Performance Days and in the US market at Functional Fabric Fair. However, our Italian supply chain partner, ITTTAI, who has a strong focus on the cycling market in that region, launched it in the fall and offered it to selected customers.

Many professional cycling teams have used our products in the past. But they were PTFE-based products. Now that we have stopped using PTFE, we are introducing something new with stormburstLT that is not only better for the environment, but also better functionally. It is lighter and has a better MVTR than PTFE.

eVent has just converted its entire product range to PTFE-free and PFAS-free. Right?

Exactly. We no longer use PTFE for consumer products, and we do not use PFAS technologies. However, for our military customers, it is a different matter; we are bound by long-term contracts and different regulations. But here, too, we are in the process of converting our suppliers and customers in this area as well where applicable.

What is the new membrane that you are using to replace PTFE based on?

We have several different PTFE-free membranes for our laminate fabrics. For alpineST, it is a polyolefin-based membrane, and we have also developed a treatment process without PFAS. Neither was easy. It is not technically trivial to replace PTFE with a polyolefin membrane. But with our experience, we have succeeded in developing a compelling product. For eVent BIO laminates, we use a plant-based membrane, and for stormburstLT laminates, we use a polyester-based membrane.

You mentioned at the beginning that you are changing the name of your product from ‘BIO’ to ‘stormST’. Why?

We launched eVent BIO six years ago. It was before COVID, but probably too early for the market. At that time, customers were more focused on recycled fabrics, and then COVID came along and shook up the market. With the focus on sustainability, ‘bio’ started showing up in a lot of places, and was used in a variety of ways. Recognizing that the product name could be confusing for both brands and consumers, we renamed the product stormST. This was not only a better fit for our other merchandising categories, but spoke more about the product’s performance and reflects the versatility of eVent stormST Also, the term ‘bio’ has become complicated because you wonder what it means. Does bio mean something is bio-based or biodegradable? It was just unclear.

Furthermore, the word bio and other terms are going to become problematic because of the expected legislation in the EU. So, we thought now is the best time to repackage this product and call it stormST before it becomes more established in a few years. It also fits in better with our other merchandising categories of alpineST, stormST, stormburstLT and windstormST.

There will still be products in the market called eVent BIO through 2025, however we are supporting our current band partners and new customers in branding these products as stormST for the Spring 2026 season.

What is the technological difference between BIO and the polyolefin membrane?

There is not one solution that replaces PTFE, therefore we offer more than one laminate technology that has a PTFE-free membrane in order to meet the performance and sustainability needs of our customers: alpineST, with a polyolefin-base solvent-free membrane. stormST, with a plant-based membrane has a greatly reduced carbon footprint and doesn’t use petroleum, and stormburstLT utilizes a polyester-based membrane for its light weight. Within each of these product lines we have laminates that are circular.

What has been the response to your all-new product line so far?

Very positive. Our customers come to eVent because we have a long history of laminate technology and innovation and have developed some interesting products. Technically, we are recognized as an industry leader.

Our products are well defined, and the laminate packages are very focused. When customers come to us, we can focus on understanding what the customer is looking for, what the technical requirements are, how are laminate fabrics can perform for most end uses. We put a curated collection together based on their needs, and in collaboration we find successful solutions for their developments.

How is eVent developing overall?

We are seeing rapid growth, especially in our Asian markets, and the western market is growing steadily. We have overcome the challenges of recent years, i.e. integration into a new company after the separation from the parent company in 2020, and at the same time the difficult situation caused by COVID, and the market is also slowly recovering. We believe it is the right time for us to focus on the eVent brand. We’ve recently completed an overhaul of our branding, a revision of the product architecture, the introduction of new products and our new PTFE-free product range. Hence the new slogan ‘Defy the elements’. This applies to almost every respect of our company- from pushing the boundaries of what is possible with our innovate laminates, to ensuring adventures aren’t curtailed due to weather conditions. ‘Defy the elements’ is the cornerstone of our brand.

Where do you produce your fabrics or laminates?

We produce in Vietnam, Taiwan, China, Europe and some in Japan. The world is very complex today and we have had to diversify our supply chain to adapt. Brands are at different stages of reviewing their supply chains and some brands are no longer sourcing from certain countries. So, we must be as flexible as possible and adapt.

As a US company, do you expect difficulties in sourcing from China?

It would be a lie to say that we are not watching this closely. We must do that, and we will respond in the best interest of our customers.

For example, many brands are trying to minimize the complexity of their supply chain, even that of their suppliers. As an example, some who manufacture in Vietnam also want to source all technologies from that country. This is not only more sustainable in terms of transport distances, but also more cost-efficient, of course. We are trying to accommodate them as much as possible.

What trends are you seeing in the market? What products are brands looking for?

We see several trends. There is a trend towards high durability, a higher abrasion category. Many sustainable technologies are not as durable, so brands are looking for suppliers that can offer the sort of durability we’ve been accustomed to with PTFE and PFAS. We’ve put a lot of energy into developing more durable products.

A second category is not new, it’s about versatility and a hybrid between outdoor and urban. Both sides are converging in fashion. These textiles are becoming more and more interesting, including for target groups whose main goal is to have a jacket for a variety of uses, not just for the backcountry, but also one that you can wear in the city.

The third category is certainly the continuous development of lightweight products, which is also the origin of stormburstLT. It goes beyond ultralight to those who want low weight but also a certain level of performance.

What plans do you have beyond that?

Our next big step is fully launching stormburstLT. We‘re also seeing a growing interest in our PFAS-free footwear solutions, so we’ll be focusing more on that area. Additionally, our plant-based footwear program continues to thrive, not only because commitments to sustainability but also due to its impressive performance. With our extensive experience in waterproof breathable footwear, we’re confident that we can add significant value with our plant-based materials for many brands.

Generally speaking, we are in continuous development to keep pace with the brands. The brands are dealing with a changing landscape: consumer preferences are changing, regulations are changing, economic scenarios are changing. All these things affect them. This will, of course, also determine our next steps.

What is the next step in sustainability?

It’s also about continuous development. We have already taken big steps and now we will see where we can improve things further. We’re not going to put something on the market just because it’s sustainable, it also has to meet the high-performance metrics expected of eVent fabrics. We want sustainability and performance to remain closely linked as we develop new products.

The outdoor industry has known eVent Fabrics for a long time, but consumers tend not to know you. Is the slogan also about building consumer trust?

I think ‘Defy the elements’ is a strong description of what the eVent culture has always been- one that challenges the status quo of what’s possible. We have always been very technology focused, and our messaging has always been very B2B. I have no doubt that brands trust us. With our new tagline, we hope that consumers can also know what the brands have known for decades- the eVent makes fabrics that push the limits, and they can rely on eVent made products to provide protection and comfort in all kinds of weather. Our new tag line is the beating heart of our focus on deeper consumer communication. It’s reflected in our new branding and future activities.