For the first time, EDM Publications conducted a survey among its readers on the topic of sustainability in January. The privilege of gaining access to an elite pool of decision-makers and asking them for their opinions was exceptionally exciting. This survey is not intended to be the only one. We will repeat it at regular intervals to track the evolution towards a greener industry.

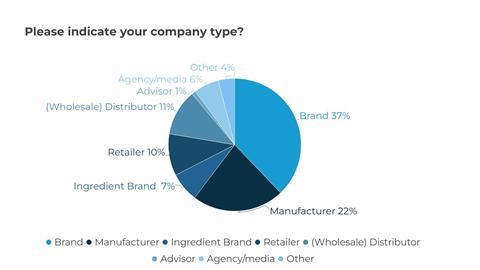

The majority of the survey’s participants come from retail and brands; the bigger rest are manufacturers or working for ingredient brands.

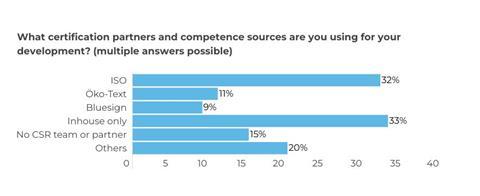

Regarding the certification and external audit of sustainability achievements, only 15 percent of the participants claimed not to have any CSR team or certification yet. 33 percent at least work on the topic in-house, which adds up to almost half of the companies not working with external audits and competence sources. For those using certification partners, ISO is the most relevant standard (32.7 percent), followed by Oeko-Tex (11.2 percent) and Bluesign (9.2 percent).

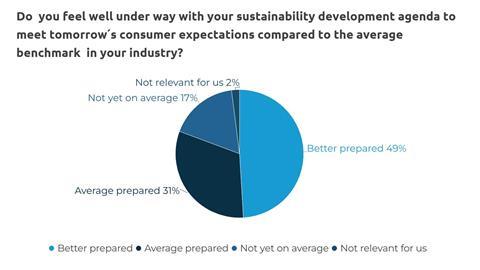

The overall sentiment is slightly optimistic: two-thirds of our readers see their companies making good (31,6 percent) or average (49 percent) progress concerning their sustainability agenda.

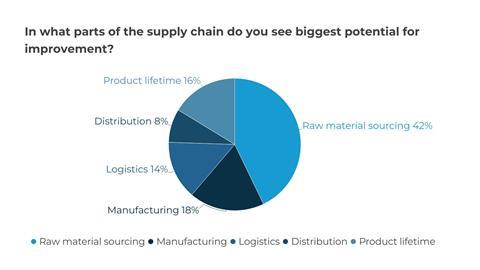

This weighting may be reflected in the evaluation of which point in the supply chain can make the fastest progress in environmental protection (see below):

- First and foremost, suppliers of fibers and fabrics are expected to act.

- By far, the biggest potential for more sustainability is seen at the very source of the manufacturing process, in the field of raw material sourcing.

- Logistics and distribution are not seen as primary and fast-acting improvement opportunities, nor is product life.

This last assessment is particularly interesting because it contradicts some of the scientific insights: While a study commissioned by W.L.Gore confirms that to date, most emissions (65 percent) occur in production, logistics and distribution, while the use (e.g., washing/impregnation) by the consumer, including subsequent disposal, causes 35 percent of all environmental damage done. The study assumed a service life of around five years for a shell jacket. The longer a garment is in use, the more this weighting shifts to the detriment of emissions during production, so a longer product lifetime may indeed quickly care for a smaller footprint. If manufacturing emissions go down, the relevance of a longer lifetime for better sustainability increases.

However, in an ideal world, a longer product wear time and a more sustainable production would go hand in hand. Today, production remains the big factor. But a closer look at the different parameters measures during production shows a shift of relevance. Renewable energy sources are gaining importance in many businesses, so the energy factor is probably becoming less important - while the issues of logistics and water consumption could become more relevant as more organic raw materials are used.

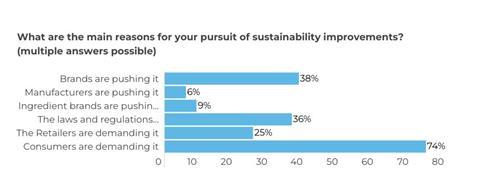

Being asked for the primary reasons for the ongoing efforts for sustainability improvement, most of the survey participants feel that consumers are demanding it. At the same time, EDM readers see brands pushing the industry, and almost the same checkmarks were counted on “laws and regulations” that push for more sustainability in the sporting goods industry. Only about a quarter of the respondents say retailers are also pressing for action. Manufacturers and ingredient brands are least seen as relevant drivers for change – although the above answers show that those pieces in the puzzle are specifically seen as having the most potential and influence on the industry’s overall environmental footprint.

Back to EDM Sustainable Business landing page.